Center Punches

A center punch is a hand-held punch which consists of a steel rod that tapers down into a point which will be hammered into the material, indicating where the hole is to be punched or drilled. Center punches are typically used in several different applications. Some of our customers use the center punches to mark the material that they wish to punch. These marks act as targets when lining up the punch and die. Some customers also use the center punches to make a dimple in their material to serve as a guide for drilling. In this case, most of the drill bits tend to have a mind of their own unless they have a recess to start in. Center punches are known throughout the industry for their reliability and durability.

Transfer Punches

A transfer punch is a hand-held punch that consists of a steel rod that tapers down to a particular outer diameter size and has a crowned center point. It is used to tightly fit the tolerances of an existing hole in a template and when hit with a hammer, it transfers the center of that hole to another piece of material. It is commonly used to precisely set locations for threaded holes, (created by drilling and tapping), to bolt an object to a surface.

The Cleveland Punch & Die Company carries many center and transfer punches in stock! For additional information please contact one of our experienced “Green Team” members at (888)451-4342 from 7am-6pm Monday through Friday.

Monday, November 15, 2010

Wednesday, November 10, 2010

Proudly Made in the USA!!

The Cleveland Punch and Die Company manufactures more than just punches and dies. We manufacture almost everything that is used on your ironworker. What better way to stock up your supply cabinet than with tooling and accessories that are proudly manufactured by a US Company? The Cleveland Punch and Die's "Green Team" is proud to be the largest stocking manufacturer in the industry. So if you are working on a deadline and need a part or a tool to finish the job, Cleveland Punch is the place to call! Let us know what style of machine you are using and we will be happy to email you one of our 17 different catalogs full of available products. You can also check out these catalogs through our tooling pages by visiting www.clevelandpunch.com/tooling.html

A sample of the products that Cleveland Punch has in stock include:

Shear Blades:

Flat Bar, Round Bar, Coper/Notcher and Angle Blades

Coupling Nuts:

Coupling Nut Wrenches, Quick Change Sleeves and Punch Nuts

We also stock accessories which include Urethane Strippers, Oversized Attachments, Die Reducers, Punch Stems and Die Blocks.

If you are in need of a blade, part or accessory for your machine, give us a call and let us show you what we have to offer! (888-451-4342)

A sample of the products that Cleveland Punch has in stock include:

Shear Blades:

Flat Bar, Round Bar, Coper/Notcher and Angle Blades

Coupling Nuts:

Coupling Nut Wrenches, Quick Change Sleeves and Punch Nuts

We also stock accessories which include Urethane Strippers, Oversized Attachments, Die Reducers, Punch Stems and Die Blocks.

If you are in need of a blade, part or accessory for your machine, give us a call and let us show you what we have to offer! (888-451-4342)

Sunday, October 31, 2010

2010 Fabtech Show

This year's Fabtech show is this week already! This year the show is being held in The Georgia World Congress Center in Atlanta, Georgia. If you are heading to the Fabtech show this week, come stop by our booth #2017 and see what's new with Cleveland Punch and Die. Joining us in our booth this year will be Mr. Karl Vogel of Component Tooling LLC and Mr. Bill Hayes of Hayes and Associates. As always, we are looking forward to the show to see our old friends and to meet new potential customers. Check out the Fabtech website at http://www.fabtechexpo.com/ for more information on the show. We hope to see you there!

Thursday, October 28, 2010

Tonnage

Does my machine have enough tonnage to be able to punch the hole that I need to punch?

Let’s say for instance, you have a 50 ton machine and you want to punch a 5/8” round hole through 1/2” A-36 mild steel. Do you have enough tonnage? Using the formula in the chart: LTS/2000 we calculate

This means that 29.45 tons of pressure is required to punch a 5/8” hole in 1/2” material. Your machine is 50 tons, so you will have enough tonnage to punch that hole.

For punching materials with a different shear strength than 60,000 PSI as listed in the tonnage charts, it is necessary to use a multiplier for calculating the proper amount of force required to punch the hole.

EXAMPLE: From our previous example, to punch a 5/8” round hole through ½” A-36 mild steel, the force required is 29.45 tons. If this material is stainless steel, with a shear strength of 70,000 PSI, (according to the chart below), the correct multiplier to use is 1.17 therefore;

29.45 tons x 1.17 = 34.46 tons, actual force required.

Let’s say for instance, you have a 50 ton machine and you want to punch a 5/8” round hole through 1/2” A-36 mild steel. Do you have enough tonnage? Using the formula in the chart: LTS/2000 we calculate

1.9635 x .500 x 60,000 =29.45 tons

2,000

This means that 29.45 tons of pressure is required to punch a 5/8” hole in 1/2” material. Your machine is 50 tons, so you will have enough tonnage to punch that hole.

For punching materials with a different shear strength than 60,000 PSI as listed in the tonnage charts, it is necessary to use a multiplier for calculating the proper amount of force required to punch the hole.

EXAMPLE: From our previous example, to punch a 5/8” round hole through ½” A-36 mild steel, the force required is 29.45 tons. If this material is stainless steel, with a shear strength of 70,000 PSI, (according to the chart below), the correct multiplier to use is 1.17 therefore;

29.45 tons x 1.17 = 34.46 tons, actual force required.

If you have any questions please contact our "Green Team" for assistance. We can be reached at 888-451-4342 from 7am to 6pm EST.

Wednesday, October 20, 2010

Punch and Die Set of The Week!

Every week we have exciting things happening at The Cleveland Punch & Die Company! This week we completed manufacturing a Half Lattice and Punch Set. This punch and die set shears a radius on a piece of flat bar and punches a hole at the same time. It’s as easy as 1, 2, 3! First, load the punch and die into your machine. Second, place the material on top of the die, then simply cycle the machine. This application has a bolt-on mechanical stripper/back gauge which acts as a guide for the material while also assisting in stripping the punch out of the die, making this application very user friendly.

This punch and die set is commonly used in the manufacturing process of handles or brackets. The customer using this particular set is shearing and punching both ends of a piece of 1-3/16” wide flat bar. The customer will then use their press brake attachment on their ironworker to bend the material into a handle or bracket.

The Cleveland Punch & Die Company is ready and eager to help you with all your special projects! We love coming up with creative solutions for all your punching needs. If you have a punching application you want to do, but are not sure how or if it can be accomplished, give us a call and we will use our 130 years of experience to design a punch and die set that will work best for you.

This punch and die set is commonly used in the manufacturing process of handles or brackets. The customer using this particular set is shearing and punching both ends of a piece of 1-3/16” wide flat bar. The customer will then use their press brake attachment on their ironworker to bend the material into a handle or bracket.

The Cleveland Punch & Die Company is ready and eager to help you with all your special projects! We love coming up with creative solutions for all your punching needs. If you have a punching application you want to do, but are not sure how or if it can be accomplished, give us a call and we will use our 130 years of experience to design a punch and die set that will work best for you.

Friday, October 8, 2010

Remember to Check Your Diagonals!

You must check the diagonal of your square sizes to ensure that the punches will pass through the bore of your coupling nut without interference. The diagonal of a square can be determined by multiplying the size of the square by 1.414, or refer to our diagonal table.

There may also be occasions when it is necessary to check the diagonal of your hexagon size to ensure that the punch will pass through the bore of your coupling nut without interference. The diagonal of a hexagon can be determined by multiplying the size of the hex by 1.1547, or refer to the hexagon diagonal table below.

You must also check the diagonal of your rectangle punches. The diagonal of a rectangle can be determined by the Pythagorean Theorem: A²+B ²=C². The "A" dimension and "B" dimension are the two sizes of the rectangle and "C" equals the diagonal of the rectangle.

You could also refer to the rectangle diagonal table below.

Example: You need to punch 13/16” square holes. Suppose your machine requires that you use F-16 punches and your coupling nut is a CN-16. You first need to turn to the coupling nut pages in your Cleveland Punch & Die Core Catalog. On the left side of the page, locate the CN-16 coupling nut. Run your finger to the right to determine the bore size. The bore size measures 1.070.

Using the diagonal formula: 13/16” x 1.414 = 1.148. This diagonal exceeds the 1.070 bore of the coupling nut which means that the corners of the square will not pass through the nut. In this case, there are two options that we have to proceed with this application. You can file out the corners of your coupling nut to allow the 13/16 square to pass through or we can make you a coupling nut with a special square bore. This can be done for rectangle and hexagons as well.

For more information on shape diagonals, please contact one of our experienced “Green Team” members at (888)451-4342 from 7am-6pm Monday through Friday.

There may also be occasions when it is necessary to check the diagonal of your hexagon size to ensure that the punch will pass through the bore of your coupling nut without interference. The diagonal of a hexagon can be determined by multiplying the size of the hex by 1.1547, or refer to the hexagon diagonal table below.

You must also check the diagonal of your rectangle punches. The diagonal of a rectangle can be determined by the Pythagorean Theorem: A²+B ²=C². The "A" dimension and "B" dimension are the two sizes of the rectangle and "C" equals the diagonal of the rectangle.

You could also refer to the rectangle diagonal table below.

Example: You need to punch 13/16” square holes. Suppose your machine requires that you use F-16 punches and your coupling nut is a CN-16. You first need to turn to the coupling nut pages in your Cleveland Punch & Die Core Catalog. On the left side of the page, locate the CN-16 coupling nut. Run your finger to the right to determine the bore size. The bore size measures 1.070.

For more information on shape diagonals, please contact one of our experienced “Green Team” members at (888)451-4342 from 7am-6pm Monday through Friday.

Friday, October 1, 2010

Trivia - Back to the Basics of Punching

Here at The Cleveland Punch and Die Company we are dedicated to providing our customers with the highest quality customer service in the industry. Our customer service personnel, known as "The Green Team", strives to provide our customers with a friendly and courteous experience every day. Our goal is to share the knowledge we have gained over the years with each and every one of our customers.

Determining the clearance between the punch and die is one of the most common issues we face on a daily basis. Today's trivia will help to address these issues!

Question #1:

If you are punching a 5/16" round hole through 1/4" A36 mild steel, what size die should be used?

Answer:

When punching 1/4" to 1/2" thick mild steel, a 1/32" clearance should be used. In this application an 11/32" die would be appropriate.

Question #2:

If you are punching a 5/8" X 1" oblong hole through 1/4" aluminum, what size die should be used?

Answer:

The suggested clearance for aluminum is 10% of the material thickness. In this particular application the clearance would be .025" (.250" thick aluminum X .010 = .025"), making the die size .650" X 1.025". While Cleveland Punch can manufacture our customers any desired die clearance, a .025" clearance would be a specialty made item. In many instances a standard 1/32" clearance would work just fine, but may produce a slight burr on the bottom of the material being punched.

Green Team Tip: The material thickness should never exceed the punch dimension!

Question #3:

If you need to punch a square hole for a 3/4" picket, what size punch and die should be used. (Material Thickness is 3/8" stainless steel)

Answer:

The suggested punch size for this application is a 25/32" to allow the square picket to be passed through the hole once it is punched. Suggested clearance for stainless steel is 18% of material thickness. This application would call for a .067" clearance (.375" thick material X .18 = .067"). This die would also be a special item. However, a 27/32" die (.843") would work just fine.

Refer to the following charts for the suggested clearance on various materials. If you have any questions please contact our "Green Team" for assistance. We can be reached at 888-451-4342 from 7am to 6pm EST.

Determining the clearance between the punch and die is one of the most common issues we face on a daily basis. Today's trivia will help to address these issues!

Question #1:

If you are punching a 5/16" round hole through 1/4" A36 mild steel, what size die should be used?

Answer:

When punching 1/4" to 1/2" thick mild steel, a 1/32" clearance should be used. In this application an 11/32" die would be appropriate.

Question #2:

If you are punching a 5/8" X 1" oblong hole through 1/4" aluminum, what size die should be used?

Answer:

The suggested clearance for aluminum is 10% of the material thickness. In this particular application the clearance would be .025" (.250" thick aluminum X .010 = .025"), making the die size .650" X 1.025". While Cleveland Punch can manufacture our customers any desired die clearance, a .025" clearance would be a specialty made item. In many instances a standard 1/32" clearance would work just fine, but may produce a slight burr on the bottom of the material being punched.

Green Team Tip: The material thickness should never exceed the punch dimension!

Question #3:

If you need to punch a square hole for a 3/4" picket, what size punch and die should be used. (Material Thickness is 3/8" stainless steel)

Answer:

The suggested punch size for this application is a 25/32" to allow the square picket to be passed through the hole once it is punched. Suggested clearance for stainless steel is 18% of material thickness. This application would call for a .067" clearance (.375" thick material X .18 = .067"). This die would also be a special item. However, a 27/32" die (.843") would work just fine.

Refer to the following charts for the suggested clearance on various materials. If you have any questions please contact our "Green Team" for assistance. We can be reached at 888-451-4342 from 7am to 6pm EST.

Monday, September 27, 2010

What style of punch and die does your machine require?

Typically, when you contact Cleveland Punch & Die to get a quote or order tooling, we will ask you for the make and model number of the machine that these tools are going to be used in. We might also ask you for the numbering on the side of the tools that you currently have for that specific machine. What if you don’t have any of the above information? No worries! Take a look at the diagrams of the punch and die anatomies displayed below. You will need to identify the head diameter, body diameter and overall length of the punch and the outside diameter and height of the die. These measurements will allow us to determine the style of punch and die that your machine requires. If you need further assistance, you can call Cleveland Punch & Die @ (888)451-4342 from 7am-6pm Monday through Friday.

Monday, September 20, 2010

Punch End Configurations

The Cleveland Punch and Die Company offers our customers a variety of different punch end configurations. Each configuration is designed for a specific purpose and application to achieve the best quality hole possible. The punch ends offered by Cleveland Punch and Die include:

- Crown Edge with Center

- This is the standard punch end configuration on all of CPD's stock punches. It is used for general purpose punching and is great for locating the punch to a predetermined spot on the material (commonly marked with a center punch).

- Flat Face

- A flat face punch is frequently used to prevent the deformation of the piece of material that is being punched. Commonly referred to as a "blanking operation" many customers will generate a flat slug of material as a finished part.

- Full Crown

- A full crown punch end should be used when punching extremely hard material such as boiler plate. This punch end will help to keep the end of the punch intact and will strengthen the overall integrity of the punch while punching hard material.

- Chisel Point

- The most common use for a chisel point punch end is to reduce the tonnage of the punching application. This is useful when punching a large diameter hole on an ironworker. Ordering a punch with a chisel point can reduce the tonnage of the application by up to 20% depending on material type and thickness. Give us a call for engineering assistance to discuss your specific application.

- Concave Shear/Crisscross Shear

- A concave or crisscross shear is common on the 28XX and 36TC tooling lines. This punch end helps to reduce the deformation on thin material by shearing the material from the outside of the punch toward the center.

Cleveland Punch and Die can manufacture any special punch end per our customer's request. Give us a call to discuss your punching application and let our 130 years of experience guide you in the right direction.

Monday, September 13, 2010

Ripping Punches

Over the years, we have had customers that want to punch an oblong hole that is longer than what their machine allows them to punch. Cleveland Punch & Die has a solution!!! We would like to introduce you to our “Ripping Punch!” A “Ripping Punch” allows you to generate an oblong hole beyond the capacity of your ironworker. First, punch a round hole the same size as the width of your oblong hole. Next, insert the guide of the ripping punch through the pre-punched hole and begin cycling the machine while feeding the material into the guide. The guide should be 1/8” to ¼” longer than the material thickness. The material thickness should not exceed 3/8” A-36 mild steel.

For more information on the “Ripping Punch”, please contact one of our experienced “Green Team” members at (888)451-4342 from 7am-6pm Monday through Friday.

For more information on the “Ripping Punch”, please contact one of our experienced “Green Team” members at (888)451-4342 from 7am-6pm Monday through Friday.

Tuesday, September 7, 2010

Countersink Punches and Dies

Cleveland Punch and Die manufactures tooling to countersink a wide variety of material. Our tools are designed to punch a hole in the material and form the material into a countersink, all in one operation. The "countersink and extrude" application is used when the material being punched/formed is thinner than 1/8". This set-up requires a countersinking punch and die to form the material properly. However, the "countersink and form" application, used when the material being punched is 1/8" or greater in thickness, can be used with a standard round die. These countersink tools will generate a standard 82° countersink in the material, a standard angle used throughout the industry.

Common products which use countersink tooling include truck beds, trailers as well as door and cabinet hinges. These products all require the head of a screw or bolt to sit flush with the material.

If you have a special countersink need, give us a call and let one of our experienced Sales Engineers design the perfect tools for your machine and application. We are available to assist your needs 7am-6pm, or you can email us at sales@clevelandpunch.com

Common products which use countersink tooling include truck beds, trailers as well as door and cabinet hinges. These products all require the head of a screw or bolt to sit flush with the material.

If you have a special countersink need, give us a call and let one of our experienced Sales Engineers design the perfect tools for your machine and application. We are available to assist your needs 7am-6pm, or you can email us at sales@clevelandpunch.com

Friday, August 27, 2010

Pipe Notch Tooling

ATTENTION all fabricators who need to cope or “fish mouth” the ends of tube or pipe…The Cleveland Punch & Die Company has the perfect set up for you! We have a variety of pipe notcher housings, tooling and striker punches in stock!!

These housings are perfect for ironworkers because you can remove your die block from your punching station and set up the striker punch in place of your regular punch. Don’t have an ironworker??? No Problem!! The pipe notcher assembly is a self-contained unit that can be used on any hydraulic or mechanically operated machine, as long as it has a bed that can secure the housing and a ram to strike the top of the tooling. The standard pipe notch housing is designed to accept punch and die assemblies up to and including 2-1/2” outside dimensions. A separate punch and die is required for each outside dimension along with a standard striker punch.

Typical end users can be found in the following industries: Automotive, Furniture, Motorcycle, Hand Railing, Scaffolding, Livestock, Fencing, Wrought Iron, Exercise, Medical and Aircraft. If you would like additional information regarding pipe notch tooling, we encourage you to contact one of our “Green Team” members for assistance! We can be reached Monday thru Friday, 7am - 6pm at 888-451-4342 or via email at sales@clevelandpunch.com.

These housings are perfect for ironworkers because you can remove your die block from your punching station and set up the striker punch in place of your regular punch. Don’t have an ironworker??? No Problem!! The pipe notcher assembly is a self-contained unit that can be used on any hydraulic or mechanically operated machine, as long as it has a bed that can secure the housing and a ram to strike the top of the tooling. The standard pipe notch housing is designed to accept punch and die assemblies up to and including 2-1/2” outside dimensions. A separate punch and die is required for each outside dimension along with a standard striker punch.

Typical end users can be found in the following industries: Automotive, Furniture, Motorcycle, Hand Railing, Scaffolding, Livestock, Fencing, Wrought Iron, Exercise, Medical and Aircraft. If you would like additional information regarding pipe notch tooling, we encourage you to contact one of our “Green Team” members for assistance! We can be reached Monday thru Friday, 7am - 6pm at 888-451-4342 or via email at sales@clevelandpunch.com.

Friday, August 20, 2010

28XX Multiple Corner Radius Tool

Are you a manufacturer of signs? Are you a fabricator concerned about the hazard of rough corners? Maybe you already use our Corner Radius tooling, but would benefit from multiple radii. Then the Cleveland Punch & Die Company’s Multiple Corner Rounding Tool could be what you need. This tool has all the same benefits as our popular Corner Radius tooling but with even more flexibility. Imagine a single Corner Radius punch and die set and multiply it by four. That’s right, four radii on one punch and die! This reduces labor due to costly changeover of tooling, and at the same time is much more efficient when a job requires multiple radii. Give us a call today and let us design a multiple corner radius tool for your specific application.

Thursday, August 12, 2010

Geka Cluster Punch Application

Are you tired of punching multiple holes one at a time? What about the time required for set up or the labor hours incurred? If this gets you thinking, then you need to ask us about a cluster punch application!! Customers are finding that it is less time-consuming and not as expensive in the long run, to punch multiple holes at the same time!

Cleveland Punch & Die has just made a quad cluster die block that holds four F-59 oblong dies to be used in a Geka Hydrocrop 110. This customer is punching four oblong holes in a 6” x 15 lbs. W beam which is ¼” thick. These are used as connecting beams which is displayed below.

Please feel free to contact our experienced engineers for additional information regarding our cluster punches. We can be reached Monday thru Friday, 7am - 6pm at 888-451-4342 or via email at sales@clevelandpunch.com.

Cleveland Punch & Die has just made a quad cluster die block that holds four F-59 oblong dies to be used in a Geka Hydrocrop 110. This customer is punching four oblong holes in a 6” x 15 lbs. W beam which is ¼” thick. These are used as connecting beams which is displayed below.

Please feel free to contact our experienced engineers for additional information regarding our cluster punches. We can be reached Monday thru Friday, 7am - 6pm at 888-451-4342 or via email at sales@clevelandpunch.com.

Wednesday, August 4, 2010

Keyhole Punches and Dies

Cleveland Punch & Die manufactures custom keyhole sets for customers with a wide array of applications. The keyhole style punch is most commonly used for mounting purposes. The next time you go to the dentist, take a look at the rubber glove box that is mounted to the wall. The glove box holder typically has two-way keyholes on the back for wall mounting. We have several customers that punch keyholes for the safety chains on tow trucks. The safety chain slides through the round part of the keyhole while the lower oblong part of the keyhole locks the chain into place.

CUSTOMER SPOTLIGHT

Paul is one of Cleveland Punch & Die’s valued customers who fabricates hanger plates! Paul says, “The keyhole punches and dies that I purchase through Cleveland Punch have amazing longevity. That is extremely important when you are punching approximately 18,000 keyholes per month! One secret that I can pass on to other fabricators punching an infinite amount of holes is to use the Punch Easy! I swab my dies with it about every ten times and have noticed that it really prolongs the life of my tooling!”

Please feel free to contact us for more information regarding keyhole punches and dies. We are available from 7am to 6pm. (888-451-4342)

CUSTOMER SPOTLIGHT

Paul is one of Cleveland Punch & Die’s valued customers who fabricates hanger plates! Paul says, “The keyhole punches and dies that I purchase through Cleveland Punch have amazing longevity. That is extremely important when you are punching approximately 18,000 keyholes per month! One secret that I can pass on to other fabricators punching an infinite amount of holes is to use the Punch Easy! I swab my dies with it about every ten times and have noticed that it really prolongs the life of my tooling!”

Please feel free to contact us for more information regarding keyhole punches and dies. We are available from 7am to 6pm. (888-451-4342)

Tuesday, August 3, 2010

International Sales Position

The Cleveland Punch and Die Company, located in Ravenna, Ohio has been the world leader in manufacturing Punches, Dies and related Components for over 130 years. Recent business conditions have presented us with the opportunity to expand our business into Latin America and Mexico. We are searching for a student or post graduate to fill an International Sales Internship position, specifically, an individual who is fluent in Spanish and able to assist our company with growth into the international market.

We are looking for an individual who is highly motivated and able to learn quickly. This internship will allow the individual to work side by side with our Sales Management Team to aggressively pursue business in the international market. This individual will be expected to develop relationships with existing customers as well as generate business with new customers.

This position is available immediately as our current International Sales Intern will be traveling to Spain next month. This will be a paid internship with a 40 hour work week for 13 weeks. I encourage any interested candidates to visit our website at http://www.clevelandpunch.com/ to become familiar with our products and services. Any interested individuals should contact Cleveland Punch at jobs@clevelandpunch.com for more information on the application process.

We are looking for an individual who is highly motivated and able to learn quickly. This internship will allow the individual to work side by side with our Sales Management Team to aggressively pursue business in the international market. This individual will be expected to develop relationships with existing customers as well as generate business with new customers.

This position is available immediately as our current International Sales Intern will be traveling to Spain next month. This will be a paid internship with a 40 hour work week for 13 weeks. I encourage any interested candidates to visit our website at http://www.clevelandpunch.com/ to become familiar with our products and services. Any interested individuals should contact Cleveland Punch at jobs@clevelandpunch.com for more information on the application process.

Friday, July 30, 2010

36 TC Cluster Punch

Cleveland Punch and Die achieved a new milestone last week by designing and manufacturing a 36TC cluster tool which allowed the customer to punch 12 holes consecutively. With the design of the 36TC punch, die and stripper plate, we made it possible for our customer to manufacture their own perforated sheets for muffler applications; ultimately generating a huge cost savings! Previously, this customer was forced to purchase material that was already perforated.

Give us a call or email one of our experienced engineers who is eager to assist you with your multi-hole punching application. We can be reached Monday thru Friday, 7am - 6pm at 888-451-4342 or via email at sales@clevelandpunch.com.

Give us a call or email one of our experienced engineers who is eager to assist you with your multi-hole punching application. We can be reached Monday thru Friday, 7am - 6pm at 888-451-4342 or via email at sales@clevelandpunch.com.

Wednesday, June 16, 2010

Lean Manufacturing

What is Lean Manufacturing?

The “Lean” concept focuses primarily on the elimination of waste from all business processes. Lean involves specific concepts that are intended to provide quality products, delivered on time at the lowest total costs.

The Lean process is based on values as defined by the customer and seeks to eliminate non value-added activities.

Here at The Cleveland Punch & Die Company we are implementing a Lean Initiative in an effort to improve ourselves, our products and our service to our customers. Please feel free to share your Lean experiences and check back from time to time for updates on our projects and progress with our Lean Manufacturing at The Cleveland Punch & Die Company.

Friday, May 14, 2010

NASCC 2010

The weather in Orlando is very warm, however the action inside the Gaylord Convention Center is very “HOT”!

The Cleveland Punch and Die Booth #613 has been very busy meeting with old friends and meeting new customers who are looking for better solutions, top notch customer support and the very finest tools manufactured in the industry. The attendance has been outstanding with a very positive vibe for the remainder of the 2010 year. We are looking forward to building and sustaining these relationships in the future. As always, please call or email us with any inquiries!

The Cleveland Punch and Die Booth #613 has been very busy meeting with old friends and meeting new customers who are looking for better solutions, top notch customer support and the very finest tools manufactured in the industry. The attendance has been outstanding with a very positive vibe for the remainder of the 2010 year. We are looking forward to building and sustaining these relationships in the future. As always, please call or email us with any inquiries!

Monday, April 12, 2010

NASCC Tickets

Give us a call if you are looking for tickets for the 2010 NASCC show in Orlando Florida. We are giving away FREE tickets with all tooling orders when you mention this blog. Check out all the info about the show here and don't forget to come see Cleveland Punch and Die in Booth 613!

Monday, March 15, 2010

Cleveland Punch en Español

Los Ponches de Cleveland y de Die sitio web de la empresa, ahora puede ser traducido a más de 52 idiomas diferentes mediante el uso de la Google Toolbar. Cleveland Punch and Die especializa en punzones, matrices, cuchillas de corte, las nueces de acoplamiento y otros accesorios para todas las máquinas de hierro de los trabajadores. Estamos encantados de ayudarle con sus herramientas de las necesidades de hoy! Llámenos a nivel local o internacional en el 800-451-4342 o envíenos un email a espanol@clevelandpunch.com. Esperamos servir a su necesidad de herramientas que viene.

Website Translation

An article written this past weekend by Miguel Helft of the New York Times discusses the use of Google Translation for web site translations. (Click here to view the article). This translation service can be used on any website by downloading the Google Toolbar.

We find this service extremely useful here at Cleveland Punch and Die to reach a whole new market of customers! With today's business market becoming more digital every day, reaching new customers online is of the utmost importance. By using this FREE service, any website can be translated into over 52 languages!

We find this service extremely useful here at Cleveland Punch and Die to reach a whole new market of customers! With today's business market becoming more digital every day, reaching new customers online is of the utmost importance. By using this FREE service, any website can be translated into over 52 languages!

Wednesday, March 10, 2010

Geka Catalog Now Online

A PDF copy of our Geka Catalog is now available on our website. Please visit our Geka Page for your copy today! As always, if you have any special application questions or if you are looking for something not covered in our catalog, just give us a call. We are available from 7am to 6pm. (888-451-4342)

Wednesday, March 3, 2010

Special Application Tooling - Architects and Artisans

Architects and Artisans are tapping into the technology we employ here at The Cleveland Punch and Die Company. Our computer aided design and manufacturing technology not only allows designers to punch unusual configurations, but also gives artisans new ideas and a fresh look on how things can be made. A punch and die set that we recently completed allowed a company to use punched out shapes from license plates to start up a jewelry line! While you may see our website and think our tools are only used in heavy sheet metal fabrication, we love the opportunity to discuss how our punches and dies can be used in new and unique ways. Do you have a new idea for a special purpose punch and die? Give us a call today and discuss it with one of our experienced engineers!

Friday, February 26, 2010

Roper Whitney Tooling

As a reminder to all of our current and prospective customers, The Cleveland Punch and Die Company manufactures tooling for all Roper Whitney Machines.

Whether you have a large press Roper Whitney or a small hand punch, CPD is the preferred manufacturer of tooling for all Roper Whitney Machines. We ship standard items in as little as 24 hours and can manufacture any special application punch and die for the Roper Machines.

Whether you have a large press Roper Whitney or a small hand punch, CPD is the preferred manufacturer of tooling for all Roper Whitney Machines. We ship standard items in as little as 24 hours and can manufacture any special application punch and die for the Roper Machines.

There is no job too big...or too small! Cleveland Punch recently manufactured a Roper Whitney punch and die for a customers special application. This rectangle was manufactured to hold a .001" tolerance on a rectangle dimension of .039" X .157". Give us a call regarding any Roper Whitney tooling, we have experienced engineers eager to help you.

Thursday, February 25, 2010

Picket Tooling and Residential Fence

Cleveland Punch and Die manufactures standard and custom Picket Tooling for the Ornamental Iron and Residential Fence Industry.

Our stock tooling generates a 60 degree picket on square tubing, but we can manufacture any specific degree per our customer's request. We stock picket tools for use with 1/2", 5/8", 3/4" and 1" square tubing. It is important to remember when you are punching a hole for a square picket to pass through, you will need a hole slightly larger than the picket itself. For example, if you are trying to pass a 1/2" square picket through a piece of material, we recommend you punch a 17/32" square hole to allow the picket to pass through the material adequately.

Cleveland Punch has also recently manufactured a custom picket tooling set for fabricating aluminum residential fence. This tooling package was customized to fit the customer's machine and specific job specifications. Call your Cleveland Punch representative today for any picket tooling needs.

Our stock tooling generates a 60 degree picket on square tubing, but we can manufacture any specific degree per our customer's request. We stock picket tools for use with 1/2", 5/8", 3/4" and 1" square tubing. It is important to remember when you are punching a hole for a square picket to pass through, you will need a hole slightly larger than the picket itself. For example, if you are trying to pass a 1/2" square picket through a piece of material, we recommend you punch a 17/32" square hole to allow the picket to pass through the material adequately.

Cleveland Punch has also recently manufactured a custom picket tooling set for fabricating aluminum residential fence. This tooling package was customized to fit the customer's machine and specific job specifications. Call your Cleveland Punch representative today for any picket tooling needs.

Tuesday, February 23, 2010

Keyways and Notches

Lately we seem to have customers inquiring about the use of keyways and notches. As a introduction for new customers and a review for our customers already using these features, lets discuss the purpose of furnishing keyways and notches on your shaped punches and dies.

The use of a keyway on a shaped punch is crucial to proper alignment. A keyway is a groove or slot cut into the head of the punch; which when used with a piece of "keystock" will align the punch properly with the stem of the machine, thus keeping the punch from rotating during the punching operation. Each machine takes a different keyway and consequently a different piece of keystock. When ordering a shaped punch and die, make sure to let your CPD customer service rep know the type of machine you are using. Also, it is very important to use a piece of "soft" or unhardened keystock to avoid punch breakage.

Ordering shaped dies with notches will keep the die aligned properly with the punch. A setscrew on most ironworker die blocks will hold the die into place. A notch, sometimes referred to as locator or flat, will allow this setscrew to properly keep the die from rotating or pulling out of the die holder. Ultimately, the use of keyways and notches on shaped punches and dies will extend the life of the punch and die.

The use of a keyway on a shaped punch is crucial to proper alignment. A keyway is a groove or slot cut into the head of the punch; which when used with a piece of "keystock" will align the punch properly with the stem of the machine, thus keeping the punch from rotating during the punching operation. Each machine takes a different keyway and consequently a different piece of keystock. When ordering a shaped punch and die, make sure to let your CPD customer service rep know the type of machine you are using. Also, it is very important to use a piece of "soft" or unhardened keystock to avoid punch breakage.

Ordering shaped dies with notches will keep the die aligned properly with the punch. A setscrew on most ironworker die blocks will hold the die into place. A notch, sometimes referred to as locator or flat, will allow this setscrew to properly keep the die from rotating or pulling out of the die holder. Ultimately, the use of keyways and notches on shaped punches and dies will extend the life of the punch and die.

Tuesday, February 16, 2010

Tooling Performance - Quality Assurance

At The Cleveland Punch and Die Company, Quality Assurance is a way of life. We begin with incoming inspection and testing of our proprietary Tool Steel. The Scanning Electron Microprobe Quantometer (SEMQ) is a useful tool in observing grain structure as well as determining the alloy constituents quantitatively and qualitatively. The SEMQ is utilized to closely analyze microstructure. Stress, Strain and Tensile testing verify Tool Steel characteristics and are an integral Quality Assurance procedure. There really is a difference with tooling manufactured by The Cleveland Punch and Die Company.

Monday, February 15, 2010

Tooling Performance - State-Of-The-Art Equipment and Processes

The Cleveland Punch and Die Company employs the latest Lean Manufacturing techniques and processes to optimize quality, delivery and value for our customers. We utilize the latest state-of-the-art machine tools and well trained, experienced journeyman machinists. Every manufacturing process is tightly controlled and monitored to ensure consistent quality and repeatability on every tool we make. With 130 years of experience, we have not only perfected the best practices for making each tool, but we have also worked to optimize our business efficiency, which maximizes value to our customers.

Friday, February 12, 2010

Tooling Performance - Heat Treatment

Here at The Cleveland Punch and Die Company, we do our Heat Treating in house under tightly controlled quality standards. This process is something we take very seriously because it provides us with a competitive advantage over our competition. Our Heat Treat cycle adds more quality and value to our tooling...thus achieving "More Holes Per Dollar".

The following diagram refers to what metallurgists call the TTT diagram. This diagram depicts heat treat optimization. These three simple steps display precisely what takes place in the heat treat process. Heat treat is indeed a science and not a guessing game or process to be taken lightly. Tool life and performance is materially affected by proper Heat Treating. There really is a difference with tooling made by The Cleveland Punch and Die Company.

The following diagram refers to what metallurgists call the TTT diagram. This diagram depicts heat treat optimization. These three simple steps display precisely what takes place in the heat treat process. Heat treat is indeed a science and not a guessing game or process to be taken lightly. Tool life and performance is materially affected by proper Heat Treating. There really is a difference with tooling made by The Cleveland Punch and Die Company.

Thursday, February 11, 2010

Tooling Performance - Highest Quality Steel & The Pursuit of Excellence

At Cleveland Punch and Die Company, we apply a systems approach to continuous improvement. Our criteria for continuous improvement demonstrates our commitment to the finest quality products and the best service in the industry.

Our punches, dies and shear blades are manufactured from our own propriety tool steels made from, and certified exclusively for The Cleveland Punch and Die Company. Metallurgical specifications of our material are carefully controlled, checked and certified to ensure consistent quality. We have tested, evaluated and improved our Tool Steel for over 100 years. This process have improved and refined our Tool Steel to ensure reliable, consistent quality in every tool. There really is a difference with Cleveland Punch and Die!

Our punches, dies and shear blades are manufactured from our own propriety tool steels made from, and certified exclusively for The Cleveland Punch and Die Company. Metallurgical specifications of our material are carefully controlled, checked and certified to ensure consistent quality. We have tested, evaluated and improved our Tool Steel for over 100 years. This process have improved and refined our Tool Steel to ensure reliable, consistent quality in every tool. There really is a difference with Cleveland Punch and Die!

Wednesday, February 10, 2010

The Hardcoating Difference

Do you have a punching application where galling or tooling life is an issue? Or, is your particular punching application preventing you from using a punching lubricant? By utilizing a variety of Cleveland Punch and Die coatings, a better tooling life can be achieved. With a delivery time of approximately one week, we are able to get these items out the door much faster than the competition! CPD offers three types of coatings depending on your requirements:

CPD MG1 Coating:

CPD MG1 Coating:

- A general purpose, gold colored coating, allowing higher punching speeds and longer tooling life.

- Especially effective when punching copper, bus bar and aluminum.

- Standard coating on our FP1 style punch.

CPD MG2 Coating:

- A harder, more lubricious coating offering better performance in steels and aluminum.

- Minimizes galling due to rapid punching.

- Commonly used in higher strength steels and when the punch size is smaller than material thickness.

- This coating is useful on "Insert" and "Style 1" Whitney™ punches.

CPD MG3 Coating:

- The most abrasion resistant and hardest coating for punching heat resistant alloys.

Call Cleveland Punch today to get more information on our coating options!

Tuesday, February 9, 2010

NASCC 2010

Come and check out Cleveland Punch and Die at the NASCC Steel Conference in Orlando, Florida this year. The show will take place May 12-15, 2010 at The Gaylord Palms Convention Center. CPD will be in booth #613. Check out this floor plan for a visual view of our location and the location of all the exhibitors at the show this year. You can also check out the NASCC website to register for the show or find out more information. As always, we are extremely excited for the opportunity to meet new customers as well as see our friends and dealers throughout the industry. We hope to see you there!

Monday, February 8, 2010

Lubrication - Punch Easy

The Cleveland Punch and Die tip of the day is perhaps the most important when it comes to punching; the use of lubrication (Punch Easy). Lubricating the tooling on a punching machine can play an influential role in extending tooling life. Understanding the forces that occur in the space between the punch and the material being punched may help explain why lubrication should be used. As the punch passes through the material, tiny amounts of the material are fused to the punch surface. As punching cycles continue, layer upon layer of material is deposited on the punch, causing the punch diameter to actually grow. The clearance between the punch and die eventually becomes so small that the punch may become pressed into the die. Lubricants act as a barrier between the punch and the material, which will significantly reduce the amount of material deposited on the punch, thus prolonging its life.

The most commonly asked question when it comes to lubrication is "Which kind of lubricant works best?" Obviously, the higher the viscosity, the greater the protection. The higher viscosity works especially well for slowly retracting punching applications. However, on fast-cycling punching machines, the protective barrier on the sides of the punch can become a sticky, air-displacing vacuum generator on the face of the punch. During the fast retraction of the punch, the slug may pull out of the die and actually adhere to the punch face.

As mentioned earlier, CPD recommends our patented lubricant Punch Easy. Punch Easy is a non-pigmented, honey colored, heavy duty, odorless punching and shearing oil for thick materials. It is used on ferrous or non-ferrous metals where scoring, galling and friction is a problem. Its is a particularly good punch and shear oil for thick, high carbon steel, armor plate, grader blade, farm implement tools and stainless steels. Punch Easy is unparalleled for high production and multiple stage punching or stamping operations. Actual pyrometer readings indicate an operating heat reduction in drawn parts, punches and dies of as much as 40%. Punch Easy is to be used for cold applications and is not designed for any hot applications. Punch Easy may be used right out of the container or diluted with light mineral oil or "Easy Thin" for less severe jobs. Punch Easy is available in quarts, gallons, 5-gallon pails, case lots, and 55 gallon drums. Easy Thin can be purchased in gallon containers and works best when diluting Punch Easy. Call your CPD representative to order your Punch Easy today!!

The most commonly asked question when it comes to lubrication is "Which kind of lubricant works best?" Obviously, the higher the viscosity, the greater the protection. The higher viscosity works especially well for slowly retracting punching applications. However, on fast-cycling punching machines, the protective barrier on the sides of the punch can become a sticky, air-displacing vacuum generator on the face of the punch. During the fast retraction of the punch, the slug may pull out of the die and actually adhere to the punch face.

As mentioned earlier, CPD recommends our patented lubricant Punch Easy. Punch Easy is a non-pigmented, honey colored, heavy duty, odorless punching and shearing oil for thick materials. It is used on ferrous or non-ferrous metals where scoring, galling and friction is a problem. Its is a particularly good punch and shear oil for thick, high carbon steel, armor plate, grader blade, farm implement tools and stainless steels. Punch Easy is unparalleled for high production and multiple stage punching or stamping operations. Actual pyrometer readings indicate an operating heat reduction in drawn parts, punches and dies of as much as 40%. Punch Easy is to be used for cold applications and is not designed for any hot applications. Punch Easy may be used right out of the container or diluted with light mineral oil or "Easy Thin" for less severe jobs. Punch Easy is available in quarts, gallons, 5-gallon pails, case lots, and 55 gallon drums. Easy Thin can be purchased in gallon containers and works best when diluting Punch Easy. Call your CPD representative to order your Punch Easy today!!

Friday, February 5, 2010

The Operator is King

The Cleveland Punch and Die tip of the day is having an educated operator. The operator controls many factors pertaining to tooling life. The operation of a punching machine is a learned skill and the operator should be familiar with all functions of the machine as well as all safety features. Extreme pressures are generated when punching holes, therefore safety should be of the utmost concern to the ironworker operator. Guards should always be in place before the operation of any machine and the user is responsible for the machine and tooling to be set-up properly in order to avoid injury. Achieving "More Holes Per Dollar" will always be a fabricator's top priority, especially in these difficult economic times. By following the basic procedures that have been discussed in this blog, tooling life will surely be extended. In turn tooling costs will be reduced, profits maximized and a competitive edge will be obtained.

Thursday, February 4, 2010

Round The Square Corner

The Cleveland Punch and Die tip of the day is to round the corner! Tool life can be influenced by the shape of the hole being punched. Tooling with sharp corners, like a square or rectangle, will break down much faster than tooling with a rounded corner. For square and rectangle holes, a 1/16" or larger corner radius will significantly extend tooling life and is recommended whenever possible.

Wednesday, February 3, 2010

Material Thickness Versus Punch Diameter

The Cleveland Punch and Die tip for the day deals with the relation of material thickness to punch diameter. The thickness of material being punched plays a significant role in punch and die life. This is especially true when punching holes where the diameter of the punch is close to, or greater than the thickness of material. During the era of the mechanical punching machine, the general rule of thumb that has been practiced is to not punch material thicker than the diameter of the punch.

Since the beginning of the hydraulic punching machine, the shock once associated with mechanical punching is minimal. Although, in certain applications, extreme pressures may be generated when holes are punched in material that is thicker than the diameter of the punch. The pressure and wear on the punch and die is greater during this type of punching and will consequently shorten tooling life. While we don't suggest engaging in this type of punching, we do know that there are applications where it can not be avoided. In these circumstances, we would recommend plenty of lubrication (Punch Easy) and extra clearance to provide some relief on the pressure exerted to the punch.

Since the beginning of the hydraulic punching machine, the shock once associated with mechanical punching is minimal. Although, in certain applications, extreme pressures may be generated when holes are punched in material that is thicker than the diameter of the punch. The pressure and wear on the punch and die is greater during this type of punching and will consequently shorten tooling life. While we don't suggest engaging in this type of punching, we do know that there are applications where it can not be avoided. In these circumstances, we would recommend plenty of lubrication (Punch Easy) and extra clearance to provide some relief on the pressure exerted to the punch.

Tuesday, February 2, 2010

Know The Material Hardness

The Cleveland Punch and Die tip for the day is knowing the hardness of the material being punched. Punches and dies used to pierce holes in A-36 steel structural beams, plate, or sheet metal should be confined to and used only on these types of materials. Attempting to punch certain materials such as armor plate or spring steel will often exceed the capabilities of the tooling, causing it to fail.

When dealing with material hardness, factors involving the thickness and diameter limitations must be considered. The diameter of the punch must be such that the punch's compressive strength is greater than the force required to pierce the hole. This punching force can be found by multiplying the material thickness by its shear strength in PSI, then multiplying by the length of the cut. The general rule of thumb is to never punch a hole where the punch dimension is less than the material thickness. (ie, 1/4" punch through 1/2" material)

The maximum allowable compressive stress depends on the type of tool steel from which the punch is made, and its hardness. For example, oil-hardened, shock resistant tool steel will withstand 300,000 PSI compressive stress before breaking and can be used at 250,000 PSI with good tool life. Other tool steels can also be considered, depending on the material to be punched. When ordering punches and dies, the user is responsible for advising Cleveland Punch and Die of the type of material, the hardness and the thickness of material being punched. Having this knowledge will allow your CPD customer service representative to provide the highest quality tool for your specific application.

When dealing with material hardness, factors involving the thickness and diameter limitations must be considered. The diameter of the punch must be such that the punch's compressive strength is greater than the force required to pierce the hole. This punching force can be found by multiplying the material thickness by its shear strength in PSI, then multiplying by the length of the cut. The general rule of thumb is to never punch a hole where the punch dimension is less than the material thickness. (ie, 1/4" punch through 1/2" material)

The maximum allowable compressive stress depends on the type of tool steel from which the punch is made, and its hardness. For example, oil-hardened, shock resistant tool steel will withstand 300,000 PSI compressive stress before breaking and can be used at 250,000 PSI with good tool life. Other tool steels can also be considered, depending on the material to be punched. When ordering punches and dies, the user is responsible for advising Cleveland Punch and Die of the type of material, the hardness and the thickness of material being punched. Having this knowledge will allow your CPD customer service representative to provide the highest quality tool for your specific application.

Monday, February 1, 2010

Check the Clearance!

The Cleveland Punch and Die tip for the day deals with the clearance between the punch and die. The clearance not only affects the punch and die life, but also the appearance of the hole. The clearance is determined by material thickness as well as the type of material being punched. Using correct clearance will result with approximately the top one third of the hole measuring the size of the punch and the bottom two thirds flaring to the approximate inside diameter of the die.

Insufficient clearance usually causes a secondary shear to be generated, resulting in additional wear on the punch and thus reducing punch and die life. Excessive clearance may result in a large flaring or "blow out" as well as a burr on the bottom of the material. Material "roll-over" may also occur along the top edge of the hole which will cause the punch's sharp edge to break down rapidly.

This figure shows an example of the effects of excessive and insufficient clearance:

No exact science exists for determining the proper clearance between the punch and die. What may work well for one particular type of material may be unsuccessful for another. However, the following chart provides good guidelines when punching A-36 mild steel:

When punching material other than mild steel, refer to the follow table:

Following these clearance guidelines will surely increase the life of the punch and die, resulting in "More Holes Per Dollar".

Insufficient clearance usually causes a secondary shear to be generated, resulting in additional wear on the punch and thus reducing punch and die life. Excessive clearance may result in a large flaring or "blow out" as well as a burr on the bottom of the material. Material "roll-over" may also occur along the top edge of the hole which will cause the punch's sharp edge to break down rapidly.

This figure shows an example of the effects of excessive and insufficient clearance:

No exact science exists for determining the proper clearance between the punch and die. What may work well for one particular type of material may be unsuccessful for another. However, the following chart provides good guidelines when punching A-36 mild steel:

Material Thickness Die Clearance

1/4" up to 1/2" 1/32"

1/2" up to 3/4" 1/16"

3/4" up to 1" 3/32"

1" and over 1/8"

When punching material other than mild steel, refer to the follow table:

Following these clearance guidelines will surely increase the life of the punch and die, resulting in "More Holes Per Dollar".

Friday, January 29, 2010

Keeping Punch Strippers in Good Repair

The Cleveland Punch and Die tip for the day involves the punch stripper. Tooling life can be influenced by the stripping mechanism which allows the punching machine to withdraw or "strip" the punch from the material after the hole has been punched. If the stripper is not used correctly, punch life may be reduced. If the bottom of the stripper is not parallel with the material, or if it is cocked or uneven, the material will act as a wedge against the punch. As the machine tries to pull the punch from the material, the lateral force wedging the punch into the material will cause the punch face to pull or flake off. In extreme cases, the punch may even be pulled apart.

Some stripping mechanisms advance with the punch and actually make contact with the material, while others are manually adjusted for the specific punching application. Manual strippers should be adjusted for minimal free play between the bottom of the stripping mechanism and the top of the material. If your stripping mechanisms begin to wear, call your Cleveland Punch & Die representative to have them replaced. We can also supply a urethane punch stripper which slips directly over the punch and aids in stripping the material off of the punch in applications where a bulky ironworker stripper is not applicable.

Some stripping mechanisms advance with the punch and actually make contact with the material, while others are manually adjusted for the specific punching application. Manual strippers should be adjusted for minimal free play between the bottom of the stripping mechanism and the top of the material. If your stripping mechanisms begin to wear, call your Cleveland Punch & Die representative to have them replaced. We can also supply a urethane punch stripper which slips directly over the punch and aids in stripping the material off of the punch in applications where a bulky ironworker stripper is not applicable.

Thursday, January 28, 2010

Die Holder Replacement

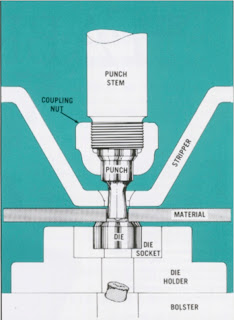

The Cleveland Punch & Die tip of the day deals with the die holder. The proper alignment of the die holder and the die socket is just as important as the punch stem. The die holder functions as a clamping device to secure the die to the punching machine and keep the die centrally located in relation to the punch. Some punching machines are equipped with a removable die socket or die insert which serves as an expendable part of the die holder (shown in the figure below).

Most of the energy transferred by the punch is passed through the die to the die holder. Because the die is harder than the die holder, a contact point may be generated between the bottom of the die and the base of the die pocket. Eventually a worn die seat may prevent the die from seating squarely. In this situation, the diameter of the die holder begins to form into an elliptical shaped hole, thus further compounding the alignment problem. The die socket or the entire die holder may have to be replaced when the die seat wears beyond acceptable limits.

The bolts or other mounting hardware which fasten the die holder to the punching machine should be checked and retightened frequently as they tend to loosen during operation. Die holders are usually equipped with die alignment locators such as a setscrew or a pin slot. These locators serve as the die's anti-rotational device when used with dies that have matching locators such as a notch, flat, pin, ect. The minimal cost of adding locators to the tooling goes a long way toward preventing unnecessary, costly tooling breakages.

Most of the energy transferred by the punch is passed through the die to the die holder. Because the die is harder than the die holder, a contact point may be generated between the bottom of the die and the base of the die pocket. Eventually a worn die seat may prevent the die from seating squarely. In this situation, the diameter of the die holder begins to form into an elliptical shaped hole, thus further compounding the alignment problem. The die socket or the entire die holder may have to be replaced when the die seat wears beyond acceptable limits.

The bolts or other mounting hardware which fasten the die holder to the punching machine should be checked and retightened frequently as they tend to loosen during operation. Die holders are usually equipped with die alignment locators such as a setscrew or a pin slot. These locators serve as the die's anti-rotational device when used with dies that have matching locators such as a notch, flat, pin, ect. The minimal cost of adding locators to the tooling goes a long way toward preventing unnecessary, costly tooling breakages.

Wednesday, January 27, 2010

Punch Stems - Get Started Properly

The Cleveland Punch & Die tip of the day deals with the punch stem. The punch stem, sometimes referred to as the ram, transfers the machine's energy into the punch. Proper alignment of the punch stem is an important factor, especially on older or heavily used punching machines. Because the punch is harder than the punch stem, the contact point between the punch stem and the head of the punch will eventually begin to wear. If this occurs, the punch will have a tendency to rock against the uneven stem surface. Checking the stem with a square and straight edge will quickly identify if a problem exists.

Most punch stems are bolted to the punching machine and can begin to loosen during the punching operation. Therefore, the bolts should be checked periodically and torqued to the manufacturer's specifications to ensure proper alignment. Some punch stems are also equipped with punch alignment locators such as a single keyway, cross keyway, vertical slots or cross "V grooves". These locators serve as an anti-rotational device when the punch is manufactured with a matching keyway. The locators are especially helpful for a quick and accurate setup when punching holes that are square, oblong, rectangle, hexagon, ect. They can also help the operator to ensure correct tooling alignment. By ordering all shaped tools with the proper keyway, tooling life will surely be extended.

Most punch stems are bolted to the punching machine and can begin to loosen during the punching operation. Therefore, the bolts should be checked periodically and torqued to the manufacturer's specifications to ensure proper alignment. Some punch stems are also equipped with punch alignment locators such as a single keyway, cross keyway, vertical slots or cross "V grooves". These locators serve as an anti-rotational device when the punch is manufactured with a matching keyway. The locators are especially helpful for a quick and accurate setup when punching holes that are square, oblong, rectangle, hexagon, ect. They can also help the operator to ensure correct tooling alignment. By ordering all shaped tools with the proper keyway, tooling life will surely be extended.

Tuesday, January 26, 2010

Coupling Nuts & Punch Holders

The Cleveland Punch and Die tip of the day deals with the coupling nut. The coupling nut or other means of fastening the punch to the machine is an important consideration to extend punch and die life. Although the coupling nut does not transfer the energy of the machine to the punch, it may prevent the punch from seating squarely against the punch stem. Coupling nut problems such as a worn seat, crushed threads or foreign material in the nut; may cause the punch to cock and strike the die when punching. The simple check of the coupling nut could prevent a costly tooling crash.

Punch holders do not experience a significant compressive force but they do experience a large tensile force. Every time the punch is pulled or "stripped" from the material, a tensile force is generated. This causes the coupling nut to stretch slightly. This stretching is most evident during the punching of thicker material. When the punch is freed from the material, the coupling nut springs back to normal. This rubber band effect will eventually cause the threads of the coupling nut to work lose. For this reason, it is extremely important that the punch holders be checked and tightened on a regular basis.

Monday, January 25, 2010

Punch and Die Alignment

The Cleveland Punch and Die tip for the day is a basic one: alignment. The punch must be aligned correctly with the die to maximize tooling life. After installing the punch and die, the operator should slowly advance the punch into the die to be sure that the punch is centered with the hole in the die. This can be checked fairly easily by making sure the clearance is equal on all sides of the punch when entering into the die.

On most ironworker punching machines a coupling nut, spanner nut or quick change sleeve is used to secure the punch to the machine. These devices are usually threaded onto a punch stem which transfers the hydraulic or mechanical energy of the machine down into the punch to generate the hole in the material. This energy transfer takes place at the top of the punch (the head), which butts up against the punch stem.

Since large amounts of pressure are exerted in this area, the base of the punch stem and the head of the punch must be flat and parallel to each other. If either is uneven, worn or cocked, the energy of the punching machine is no longer transferred through the center of the punch. This usually causes the punch to cock and strike the die, ultimately resulting in the punch cracking or failing.

By performing a quick check of punch and die alignment each time the tooling is changed, the punch and die life will be extended, resulting in "More Holes Per Dollar".

On most ironworker punching machines a coupling nut, spanner nut or quick change sleeve is used to secure the punch to the machine. These devices are usually threaded onto a punch stem which transfers the hydraulic or mechanical energy of the machine down into the punch to generate the hole in the material. This energy transfer takes place at the top of the punch (the head), which butts up against the punch stem.

Since large amounts of pressure are exerted in this area, the base of the punch stem and the head of the punch must be flat and parallel to each other. If either is uneven, worn or cocked, the energy of the punching machine is no longer transferred through the center of the punch. This usually causes the punch to cock and strike the die, ultimately resulting in the punch cracking or failing.

By performing a quick check of punch and die alignment each time the tooling is changed, the punch and die life will be extended, resulting in "More Holes Per Dollar".

Friday, January 22, 2010

More Holes Per Dollar

As a punch and die manufacturer we are continually striving to service the individuals and companies in the Steel Fabricating Industry with focus on improving their productivity and efficiency. In these tough economic times it seems that everyone is trying to improve anything they can.

Over the next few weeks we will be outlining numerous methods and activities that are considered standard practices at The Cleveland Punch and Die Company. These practices are intended to provide valuable assistance to our customers in an effort to extend tooling life. "More Holes Per Dollar" is our way of describing the passionate pursuit of improvement by each and every one of us here at CPD.

Helping our customers get "More Holes Per Dollar" starts with the fundamentals, the steel used in the making of the tool. By melting our own proprietary tool steel, we are able to deliver a longer lasting tool. Whether it is a punch, a die, a shear blade or a component part, our steel has been designed to last longer than that of the competition.

I would like to encourage this blog to be that of an open forum. If anyone has any questions or suggestions, please feel free to leave a comment or email me directly. Thanks for taking the time to check out our blog. I look forward to more posts and talking with you all in the future.

Kyle Brown

kbrown@clevelandpunch.com

Over the next few weeks we will be outlining numerous methods and activities that are considered standard practices at The Cleveland Punch and Die Company. These practices are intended to provide valuable assistance to our customers in an effort to extend tooling life. "More Holes Per Dollar" is our way of describing the passionate pursuit of improvement by each and every one of us here at CPD.

Helping our customers get "More Holes Per Dollar" starts with the fundamentals, the steel used in the making of the tool. By melting our own proprietary tool steel, we are able to deliver a longer lasting tool. Whether it is a punch, a die, a shear blade or a component part, our steel has been designed to last longer than that of the competition.

I would like to encourage this blog to be that of an open forum. If anyone has any questions or suggestions, please feel free to leave a comment or email me directly. Thanks for taking the time to check out our blog. I look forward to more posts and talking with you all in the future.

Kyle Brown

kbrown@clevelandpunch.com

Monday, January 18, 2010

Optimistic 2010

As we begin 2010 we are optimistic that business conditions are improving. Most economic indicators are showing upward momentum. This is great news for everyone in the metalworking industry!

Cleveland Punch will celebrate its 130th Anniversary in 2010. We would like to express our appreciation to our many loyal customers for making this milestone possible. We are planning several "Economic Stimulus" events to reward our hardworking, loyal customers.

Please check out our website's News Page at www.clevelandpunch.com/news for current Promotions and Anniversary Celebration Events. Best wishes for a Prosperous 2010.

-Dan L. Brown, President

Subscribe to:

Posts (Atom)

.jpg)

.jpg)