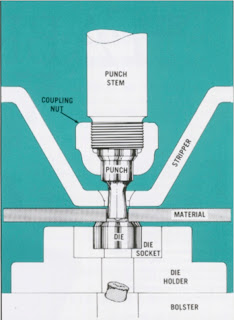

The Cleveland Punch & Die tip of the day deals with the die holder. The proper alignment of the die holder and the die socket is just as important as the punch stem. The die holder functions as a clamping device to secure the die to the punching machine and keep the die centrally located in relation to the punch. Some punching machines are equipped with a removable die socket or die insert which serves as an expendable part of the die holder (shown in the figure below).

Most of the energy transferred by the punch is passed through the die to the die holder. Because the die is harder than the die holder, a contact point may be generated between the bottom of the die and the base of the die pocket. Eventually a worn die seat may prevent the die from seating squarely. In this situation, the diameter of the die holder begins to form into an elliptical shaped hole, thus further compounding the alignment problem. The die socket or the entire die holder may have to be replaced when the die seat wears beyond acceptable limits.

The bolts or other mounting hardware which fasten the die holder to the punching machine should be checked and retightened frequently as they tend to loosen during operation. Die holders are usually equipped with die alignment locators such as a setscrew or a pin slot. These locators serve as the die's anti-rotational device when used with dies that have matching locators such as a notch, flat, pin, ect. The minimal cost of adding locators to the tooling goes a long way toward preventing unnecessary, costly tooling breakages.

No comments:

Post a Comment